Table of Contents

11 Ways to Cut Titanium: A Comprehensive Guide

Titanium, a strong and lightweight metal, is widely used in various industries such as aerospace, automotive, and medical. However, cutting titanium can be a challenging task due to its high strength and low thermal conductivity. In this article, we will explore 11 effective ways to cut titanium, providing you with valuable insights and techniques to overcome this difficulty.

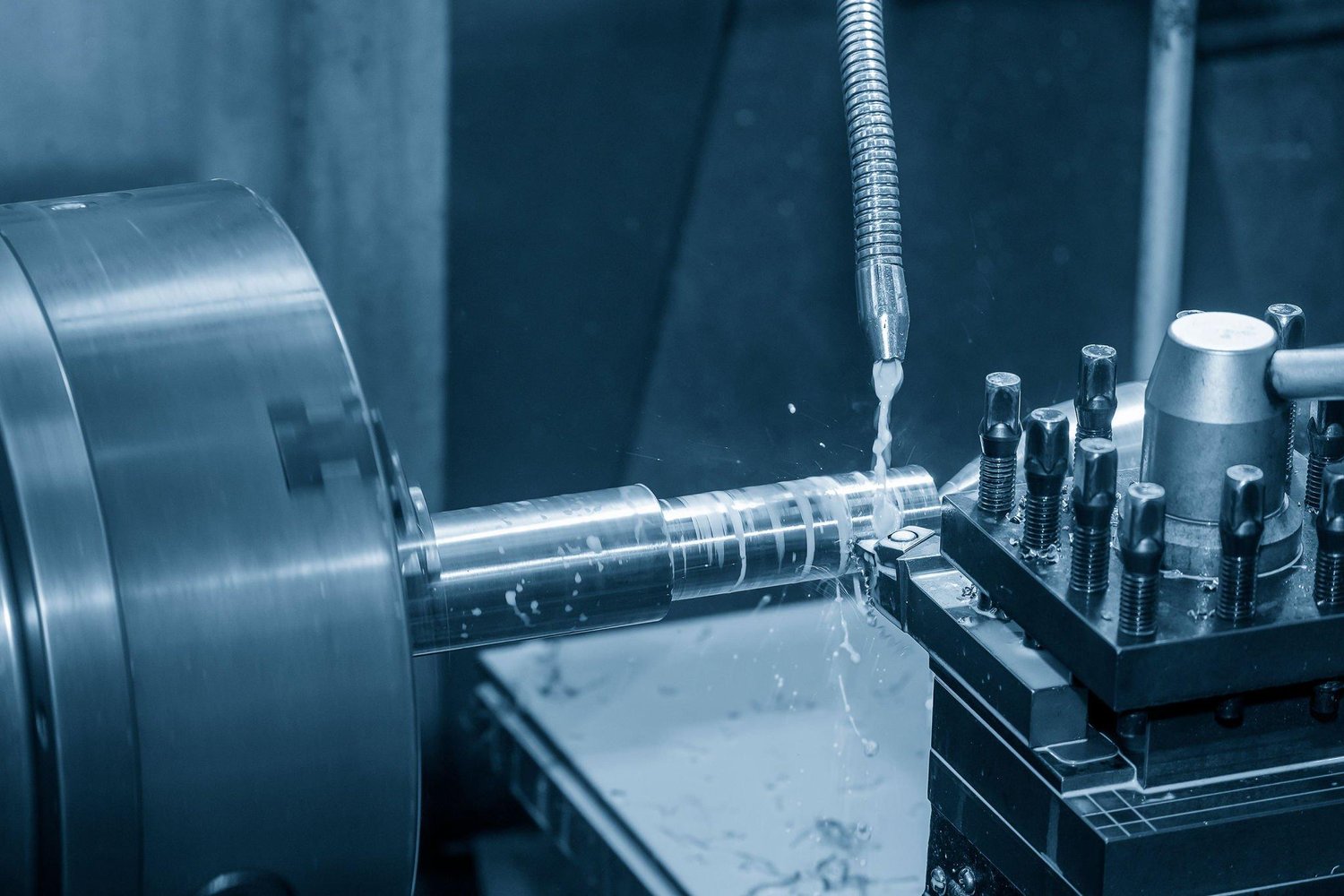

1. Traditional Machining Methods

Traditional machining methods, such as turning, milling, and drilling, can be used to cut titanium. However, special considerations are required due to its high strength and low heat conductivity. It is essential to use sharp tools, reduce cutting speeds, and apply ample coolant to prevent overheating and tool wear.

2. Abrasive Waterjet Cutting

Abrasive waterjet cutting is a popular method for cutting titanium. It involves using a high-pressure jet of water mixed with abrasive particles to erode the titanium material. This method is highly precise and does not generate heat-affected zones, making it suitable for complex shapes and delicate parts.

3. Laser Cutting

Laser cutting is another effective technique for cutting titanium. It utilizes a high-powered laser beam to melt and vaporize the material, creating a clean and precise cut. Laser cutting is particularly useful for thin sheets of titanium and intricate designs.

4. Plasma Cutting

Plasma cutting involves using a plasma torch to cut through titanium. The torch generates a high-temperature plasma arc that melts and blows away the material. This method is suitable for cutting thick titanium plates and is often used in heavy-duty industrial applications.

5. Electrical Discharge Machining (EDM)

Electrical Discharge Machining (EDM) is a non-traditional method that uses electric sparks to erode the titanium material. It is highly precise and can cut intricate shapes without creating mechanical stress. EDM is commonly used for cutting hardened titanium alloys and for wire-cutting applications.

6. Bandsaw Cutting

Bandsaw cutting is a cost-effective method for cutting titanium. It involves using a continuous metal blade with teeth to cut through the material. Bandsaw cutting is suitable for straight cuts and can be used for cutting titanium bars, pipes, and profiles.

7. Shearing

Shearing is a simple and fast method for cutting thin sheets of titanium. It involves using a shear or guillotine tool to apply a high force on the material, causing it to fracture along a straight line. Shearing is commonly used for cutting titanium foils and thin plates.

8. Plasma Arc Cutting

Plasma arc cutting is a thermal cutting method that uses a high-velocity jet of ionized gas to melt and remove the titanium material. This process is suitable for cutting thick titanium sheets and plates. However, it may result in a wider heat-affected zone compared to other methods.

9. Rotary Cutting Tools

Rotary cutting tools, such as carbide end mills and drills, can be used to cut titanium. These tools are designed to withstand the high cutting forces and temperatures generated during the cutting process. It is important to select the appropriate tool geometry and cutting parameters for optimal results.

10. Ultrasonic Machining

Ultrasonic machining is a non-traditional method that uses ultrasonic vibrations and abrasive slurry to cut titanium. The vibrations induce micro-scale chipping, enabling efficient material removal. Ultrasonic machining is suitable for cutting intricate shapes and hard-to-machine titanium alloys.

11. Wire EDM Cutting

Wire Electrical Discharge Machining (EDM) is a specialized method for cutting titanium. It uses a thin, electrically conductive wire to cut through the material. Wire EDM is highly precise and can achieve tight tolerances. It is commonly used for cutting complex titanium parts with high accuracy.