Table of Contents

Introduction

If you are in search of a material that is strong, durable, and ideal for various applications, then titanium is definitely a great choice. In particular, 10mm titanium bar is one of the most versatile and widely used products in the industry. In this article, we will take a closer look at this amazing material, its features, uses, benefits, and more.

What is 10mm Titanium Bar?

10mm titanium bar is a solid, cylindrical shape product made of titanium metal. It consists of a single, uniform diameter, making it easy to machine, shape, or cut into any desired size or form. 10mm titanium bar is classified as a Grade 5 Ti-6Al-4V alloy, which is a blend of titanium, aluminum, and vanadium. This alloy is known for its extreme strength-to-weight ratio, excellent corrosion resistance, and biocompatibility.

Properties

10mm titanium bar has several unique properties that make it the top choice for various applications. These properties include:

- High strength and durability: 10mm titanium bar is exceptionally strong and can withstand high temperatures, pressure, and stress.

- Lightweight: Titanium is significantly lighter than steel and other metals, making it perfect for use in aerospace, automotive, and medical fields.

- Corrosion-resistant: Titanium is highly resistant to seawater, nitric acid, chloride, and other harsh chemicals.

- Biocompatible: Titanium is a biocompatible material that is non-toxic, non-allergenic, and has low or no rejection rates in human tissue.

Applications

10mm titanium bar is used in various industries because of its excellent properties and benefits. Some of its common applications include:

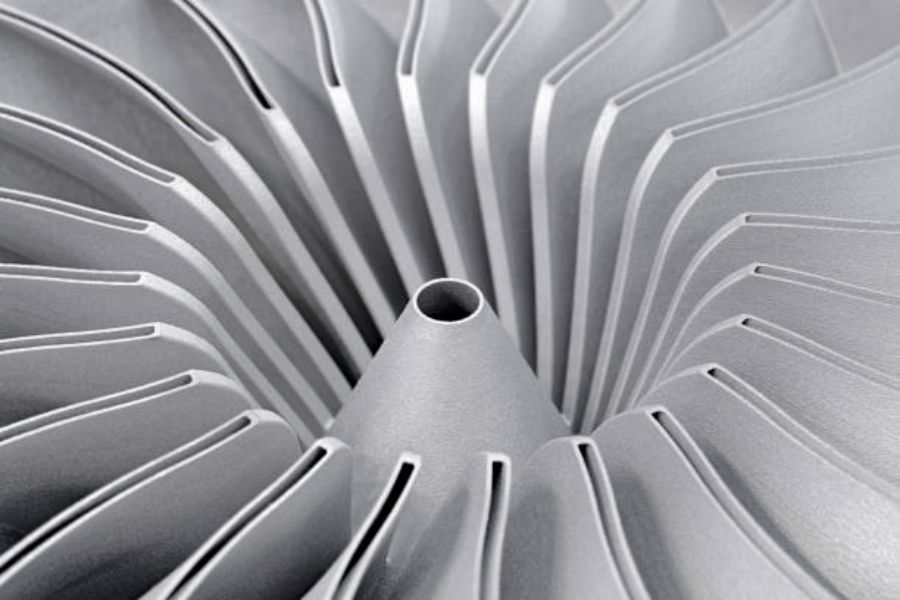

- Aerospace: Titanium is used in the aerospace industry for its lightweight and strength properties. It is used to make aircraft components, such as landing gears, engines, and structural parts.

- Medical: Titanium is used in medical implants, like joint replacements, bone screws, and dental implants, due to its biocompatibility and corrosion resistance.

- Oil and Gas: Titanium is used in oil and gas industries for its excellent corrosion resistance to seawater and other harsh chemicals.

- Sports equipment: Titanium is used in the manufacturing of sports equipment, such as bicycle frames, golf clubs, and tennis racquets due to its lightweight and strength properties.

Advantages

There are several benefits to using 10mm titanium bar over other materials. These benefits include:

- Weight saving: As titanium is much lighter than other metals, it can help reduce the weight of structures in various applications.

- High strength-to-weight ratio: Titanium has a greater strength-to-weight ratio than most other materials, making it ideal for applications where strength is a critical factor.

- Corrosion resistance: Titanium does not corrode in most environments, making it long-lasting and perfect for use in marine or corrosive environments.

- Lifetime durability: Titanium's exceptional strength and durability make it a long-lasting solution, which leads to fewer maintenance requirements and overall cost savings.

Machinability

10mm titanium bar is relatively easy to machine, form, and weld compared to other materials. The cutting tools used for machining titanium are typically made of high-speed steel or carbide tipped tools. Care must be taken to avoid burning during the grinding or cutting process as this will lead to the titanium losing its high strength properties due to heat treatment changes. Lubrication and slow speeds work well for achieving the desired results when machining titanium.

Disadvantages

While titanium has many benefits, it also has some drawbacks. These are:

- Higher cost: Titanium is a more expensive material, which makes it more challenging to purchase and use than many other materials.

- Difficult to cast: Unlike other metals, titanium is challenging to cast and form into desired shapes, making it harder to manufacture some products.

- Hardness: Titanium is a hard metal that can cause wear and tear on cutting tools during the machining process, which requires specific tools for optimal results.

Maintaining 10mm Titanium Bar

Proper maintenance is essential to keep 10mm titanium bar in excellent condition. A few tips to follow include:

- Avoid contact with other metals to prevent galvanic corrosion.

- Store it in a dry place free from moisture and dirt.

- Never expose titanium to temperatures exceeding 1400°F (760°C) to preserve its strength properties.

- Do not use abrasives to maintain the finish of the titanium bar; instead, use soapy water or mild solvent such as IPA.

Conclusion

10mm titanium bar is an exceptional material with superior properties that make it suitable for a wide range of applications. It is lightweight, strong, biocompatible, and corrosion-resistant, making it an ideal choice for aerospace, medical, and sports equipment industries. While it does have some disadvantages, proper maintenance, and machining techniques can help you overcome these issues. If you're looking for a material that offers high performance and durability, 10mm titanium bar is an excellent choice.