Table of Contents

The Remarkable Health Benefits of Titanium Tubes in Medical Devices

Medical devices have come a long way in recent years, thanks to advancements in technology and materials. One material that has gained significant attention in the medical field is titanium. Titanium tubes, in particular, have proven to be incredibly beneficial in medical device applications, offering a range of advantages that contribute to improved patient outcomes. In this article, we will explore the various health benefits of titanium tubes in medical devices.

1. Enhanced Biocompatibility

One of the key advantages of using titanium tubes in medical devices is their excellent biocompatibility. Biocompatibility refers to the ability of a material to coexist with living tissues or organisms without causing any adverse reactions. Titanium is known for its high biocompatibility, making it an ideal choice for medical devices that come into contact with bodily tissues or fluids.

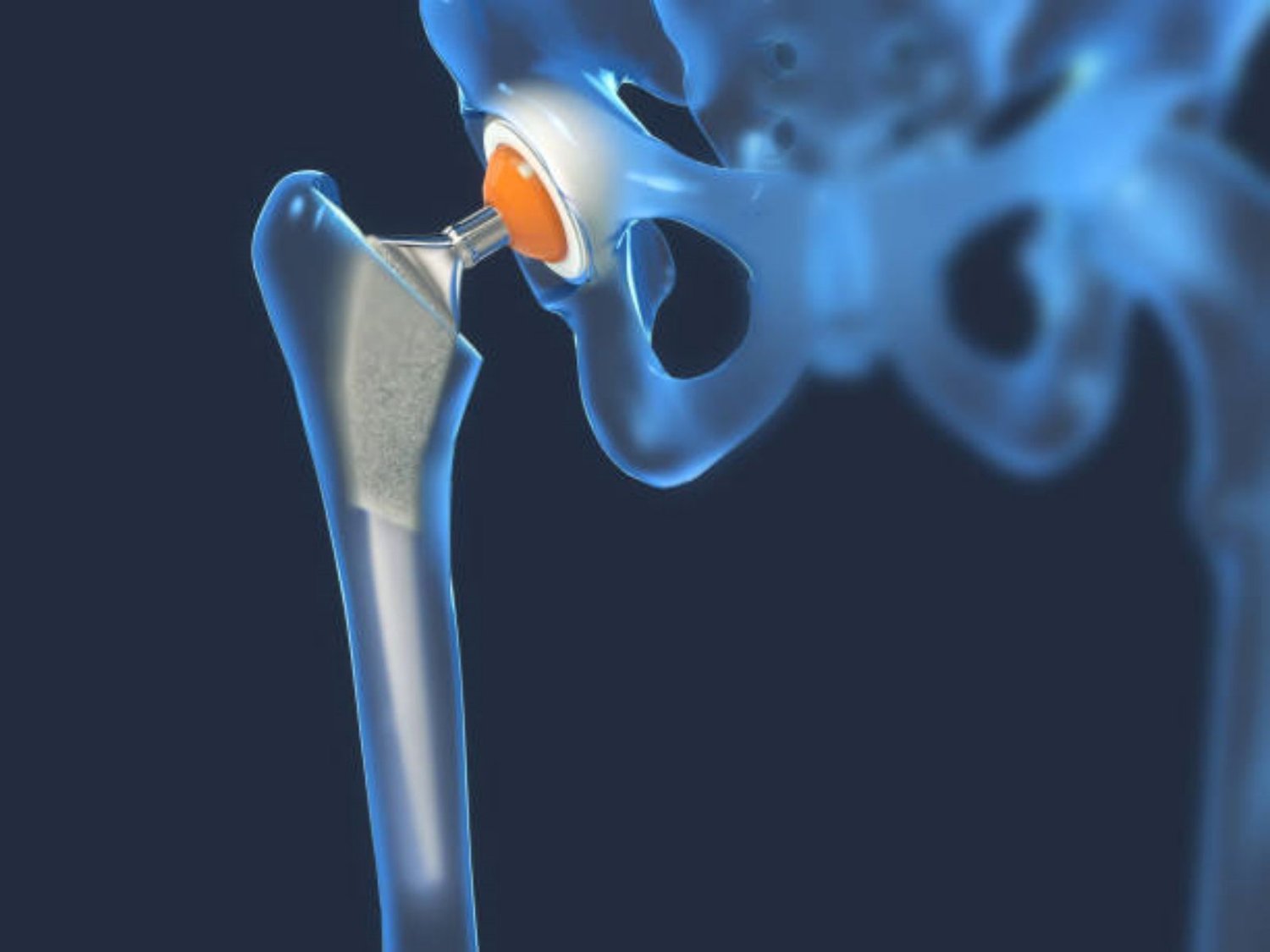

When titanium tubes are used in medical devices, they integrate seamlessly with the surrounding tissues, minimizing the risk of rejection or allergic reactions. This is particularly important in implantable devices such as pacemakers, joint replacements, and dental implants, where long-term compatibility is crucial.

2. Corrosion Resistance

Another remarkable feature of titanium tubes is their exceptional corrosion resistance. Medical devices often come into contact with bodily fluids, which can be highly corrosive. Titanium's corrosion resistance ensures that the tubes remain intact and free from degradation even in such harsh environments.

This corrosion resistance not only prolongs the lifespan of the medical devices but also prevents the release of harmful substances into the body. It ensures that the devices maintain their structural integrity, reducing the need for frequent replacements and the associated risks and costs.

3. Strength and Durability

Titanium tubes exhibit remarkable strength and durability, making them highly suitable for medical device applications. Despite being lightweight, titanium is as strong as steel and can withstand extreme conditions without deformation or failure.

This strength and durability make titanium tubes ideal for devices that need to withstand high pressure, such as vascular stents or catheters. Additionally, their robust nature allows for thinner walls, enabling the design of more compact and minimally invasive medical devices.

4. Excellent Fatigue Resistance

Medical devices often undergo repetitive loading and unloading cycles during their lifetime. Titanium tubes excel in this aspect, as they possess excellent fatigue resistance. Fatigue resistance refers to a material's ability to withstand cyclic loading without experiencing structural damage or failure.

Titanium's superior fatigue resistance ensures that medical devices incorporating titanium tubes can endure prolonged use without compromising their performance. This is particularly crucial in devices like orthopedic implants or cardiovascular stents, where continuous stress and strain are involved.

5. Non-Magnetic Properties

Many medical procedures involve the use of magnetic resonance imaging (MRI) or other imaging techniques. In such cases, it is essential for the medical devices to be non-magnetic to prevent interference with the imaging process.

Titanium tubes possess non-magnetic properties, making them well-suited for medical devices that may need to undergo MRI scans. This ensures accurate imaging results and eliminates any potential risks or complications.

6. Thermal Stability

Titanium tubes exhibit exceptional thermal stability, allowing them to maintain their properties even under extreme temperature variations. This makes them highly suitable for medical devices that may be exposed to temperature fluctuations during sterilization processes or in the body.

The thermal stability of titanium tubes ensures that the devices retain their structural integrity and functionality, eliminating the risk of deformation or failure due to temperature changes.

7. Antibacterial Properties

Bacterial infections are a significant concern in medical settings, often leading to complications and prolonged hospital stays. Titanium tubes have been found to possess inherent antibacterial properties, which can help mitigate the risk of infections.

Studies have shown that titanium's antibacterial properties can inhibit the growth of various pathogenic bacteria, reducing the chances of infection in medical devices. This is particularly beneficial in devices like catheters or prosthetic implants where the risk of bacterial colonization is high.

8. Radiopacity

Radiopacity refers to the ability of a material to block or attenuate X-rays, making it visible on radiographic images. Titanium tubes exhibit excellent radiopacity, allowing medical professionals to accurately visualize the position and placement of devices during procedures.

This property is especially valuable in devices such as endovascular stents or orthopedic implants, where precise positioning is critical for successful outcomes. The radiopacity of titanium tubes ensures that medical professionals can monitor the devices post-implantation and detect any potential complications or issues.

9. Ease of Manufacturing

Titanium tubes offer ease of manufacturing, allowing for the production of complex medical devices with intricate designs. Titanium's excellent machinability and formability enable the creation of customized devices that perfectly suit individual patient needs.

This ease of manufacturing also contributes to cost-effectiveness, as it reduces the time and resources required for production. It allows medical device manufacturers to efficiently create high-quality devices that meet the specific requirements of healthcare professionals and patients.

10. Compatibility with Other Materials

Titanium tubes exhibit great compatibility with other materials commonly used in medical device manufacturing. This compatibility enables the creation of hybrid devices that harness the benefits of multiple materials.

For instance, titanium can be combined with biocompatible polymers to develop composite devices that offer enhanced functionality and performance. This versatility allows for the development of innovative medical devices that provide superior patient outcomes.