Table of Contents

Titanium sheets have become indispensable across diverse industries owing to their exceptional properties and versatility. Known for their lightweight yet robust nature, these sheets find applications in various sectors.

Here, we delve into the multifaceted applications of titanium sheets in different industries, the advantages they offer, the various types available, and more, drawing insights from STA, a leading titanium sheet supplier in China.

Applications of Titanium Sheets in Different Industries:

The adaptability of titanium sheets makes them suitable for a broad spectrum of applications in different sectors. In the aerospace industry, their use in aircraft components such as wings, fuselage sections, and engine parts is driven by their lightweight and high-strength properties. The corrosion resistance of titanium also positions it as an excellent material for marine applications, including shipbuilding and offshore structures.

In the medical industry, titanium sheets are extensively employed for implants, surgical instruments, and equipment. The material's biocompatibility, corrosion resistance, and ability to integrate with living tissue make it an ideal choice for medical applications. Furthermore, titanium sheets find applications in the chemical industry, where they are utilized in reactors, heat exchangers, and storage tanks due to their exceptional corrosion resistance.

The automotive industry commonly uses titanium sheets for various components, including exhaust systems, suspension springs, and engine parts, benefiting from their high strength and heat resistance properties that contribute to improved performance and fuel efficiency. Additionally, titanium sheets are employed in the sports and recreation industry for products like bicycle frames, golf clubs, and tennis rackets, where lightweight and durability are paramount.

Understanding the Different Types of Titanium Sheets:

Most titanium sheet suppliers offer several types of titanium sheets, each with unique characteristics. Commercially pure titanium sheets are the most common type, classified into Grade 1, Grade 2, Grade 3, and Grade 4. These unalloyed sheets exhibit excellent corrosion resistance and formability, making them prevalent in chemical processing, marine, and aerospace industries.

Titanium alloy sheets, another category, result from combining titanium with other elements to enhance specific properties. These alloys fall into three groups: alpha alloys, near-alpha alloys, and alpha-beta alloys. Alpha alloys are known for their high strength and heat resistance, while near-alpha alloys offer improved toughness. Alpha-beta alloys provide a balance between strength, ductility, and weldability, making them versatile for a range of applications.

The Importance of Quality Control in Titanium Sheet Manufacturing:

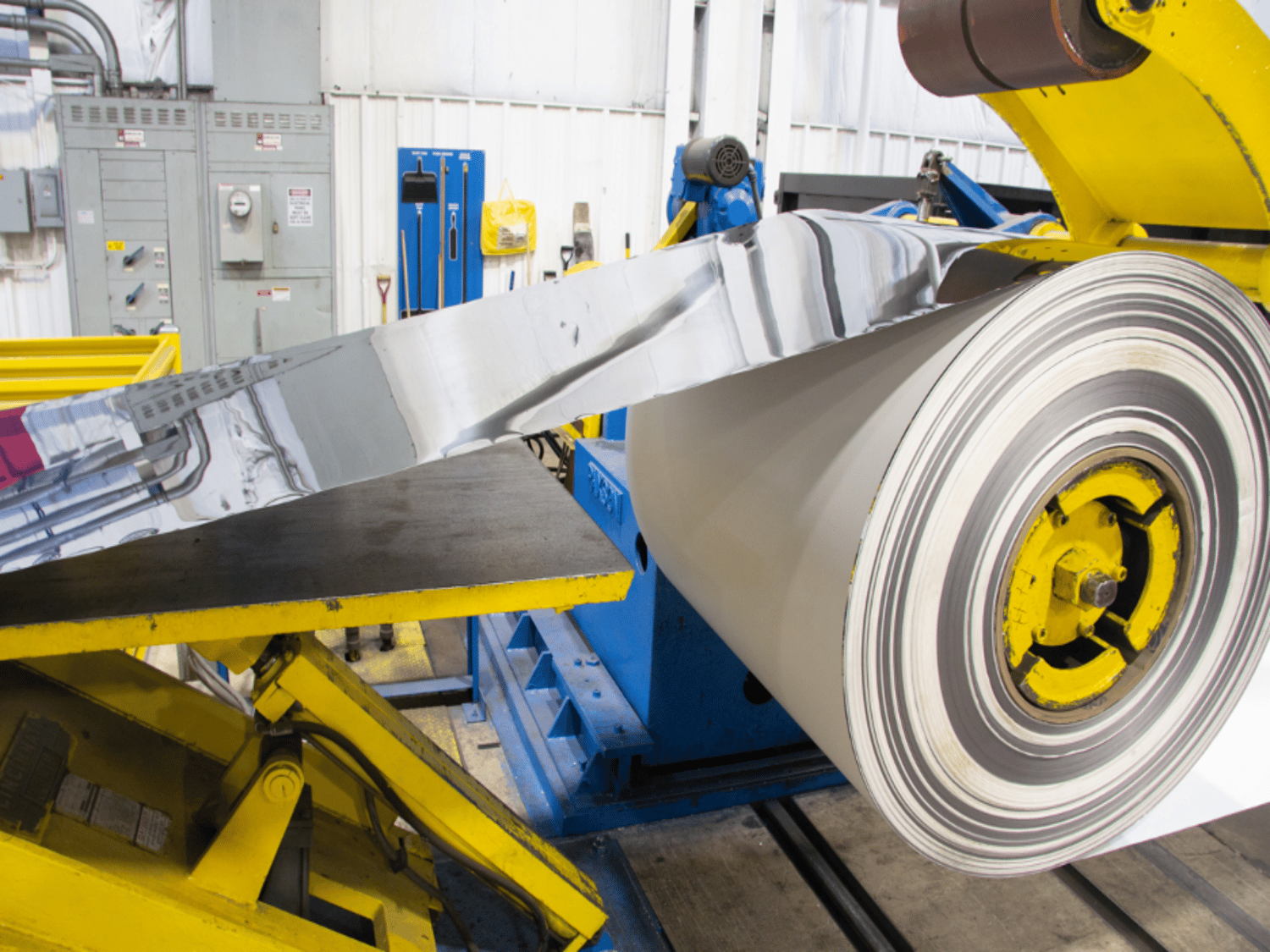

Quality control is paramount in the manufacturing of titanium sheets to ensure they meet required specifications and standards. The manufacturing process involves various steps, including melting, casting, rolling, and heat treatment, all of which must be closely monitored to minimize defects and maintain consistent quality.

Material testing is a critical aspect of quality control, involving thorough checks of chemical composition, mechanical properties, and dimensional accuracy. Tests such as tensile testing, hardness testing, and spectroscopic analysis help identify deviations from specified requirements, allowing for corrective actions.

Inspection is equally crucial during the manufacturing process to detect surface defects like cracks, pits, or scratches. Dimensional inspections ensure that the sheets meet specified thickness, width, and length requirements.

Through rigorous quality control measures, titanium sheet manufacturers, such as STA, can guarantee products that meet the highest standards and excel in diverse applications.

Are you a manufacturer in search of a reliable titanium sheet supplier?

If so, STA is here to assist you. With our extensive experience, advanced manufacturing capabilities, and unwavering commitment to quality, we have the expertise to provide you with high-quality materials for your next project.

Contact us today to learn more about how we can support your manufacturing needs.